As opposed to a traditional BOM, an equipment BOM lists all the tools and equipment needed to make a product, rather than the underlying materials.

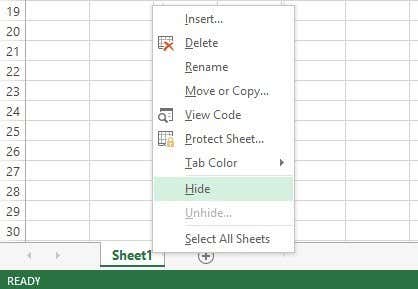

SHEET CONTENT TOO FAR INDENTED EXCEL FOR MAC 2011 SOFTWARE

Because users will need to reorganize part combinations for each variation, most organizations use “configurator” software for CBOMs, although you can also manage them manually. Configurable BOM (CBOM): A configurable BOM relies on a modular BOM structure, but is used for products that offer many different options or arrangements.It is different from an EBOM in that it does not focus on the engineering design, but rather on the tangible parts and how they relate to each other. Manufacturing BOM (MBOM): An MBOM lists all the physical parts needed to successfully manufacture a product.This differs from a modular BOM in that it reflects the engineering needs, rather than simply listing required materials. Engineering BOM (EBOM): An EBOM is a bill of materials that depicts the product components as designed by the engineers.The components are organized in parent-child relationships from left to right and appear “indented” or on multiple levels. A single-level BOM has only one level of sub-assemblies, while multi-level or indented BOMs have multiple levels. Modular BOM: In a modular BOM, you list components hierarchically to describe all sub-assemblies within the completed product.general consumer electronics product).” Below is a list of the most common types of BOMs: “Its intricacy and importance can vary depending on the size of the business, complexity of the product, and risk to the end customer (e.g., medical device vs. “A bill of materials can come in many different flavors,” says Pritchard. Therefore, it is essential to have an accurate, comprehensive, and up-to-date list of all the raw materials you will need to successfully complete your product.

Several parties often interact with or depend on a bill of materials, including internal departments, industry experts, project or product stakeholders, and external vendors or suppliers. “It is, at its core, a list of all the items necessary to carry out production of a physical good.” “A bill of materials (or BOM) is at the heart of a design well suited for manufacture,” he says. John Pritchard is a co-founder and Lead Hardware Engineer at HabitAware, Inc., and an adjunct instructor at the University of Minnesota, where he teaches an introductory course about the Internet of Things (IoT). WorkApps Package your entire business program or project into a WorkApp in minutes.

Digital asset management Manage and distribute assets, and see how they perform.Resource management Find the best project team and forecast resourcing needs.Intelligent workflows Automate business processes across systems.Governance & administration Configure and manage global controls and settings.Streamlined business apps Build easy-to-navigate business apps in minutes.Data connections Synchronize data across critical business systems.Secure request management Streamline requests, process ticketing, and more.Process management at scale Deliver consistent projects and processes at scale.Content management Organize, manage, and review content production.Workflow automation Quickly automate repetitive tasks and processes.Team collaboration Connect everyone on one collaborative platform.Smartsheet platform Learn how the Smartsheet platform for dynamic work offers a robust set of capabilities to empower everyone to manage projects, automate workflows, and rapidly build solutions at scale.

0 kommentar(er)

0 kommentar(er)